Our line can also be equipped with units for slicing baguettes or for the production of hamburger or hotdog buns. This means that our roll line is able to cover the commercial needs of any industrial bakery.

Selecting a suitable 4–6 row divider depends primarily upon the performance capacity of the line as well as the type and weight of the product. The entire line is synchronized, and is operated from a centralized control panel.

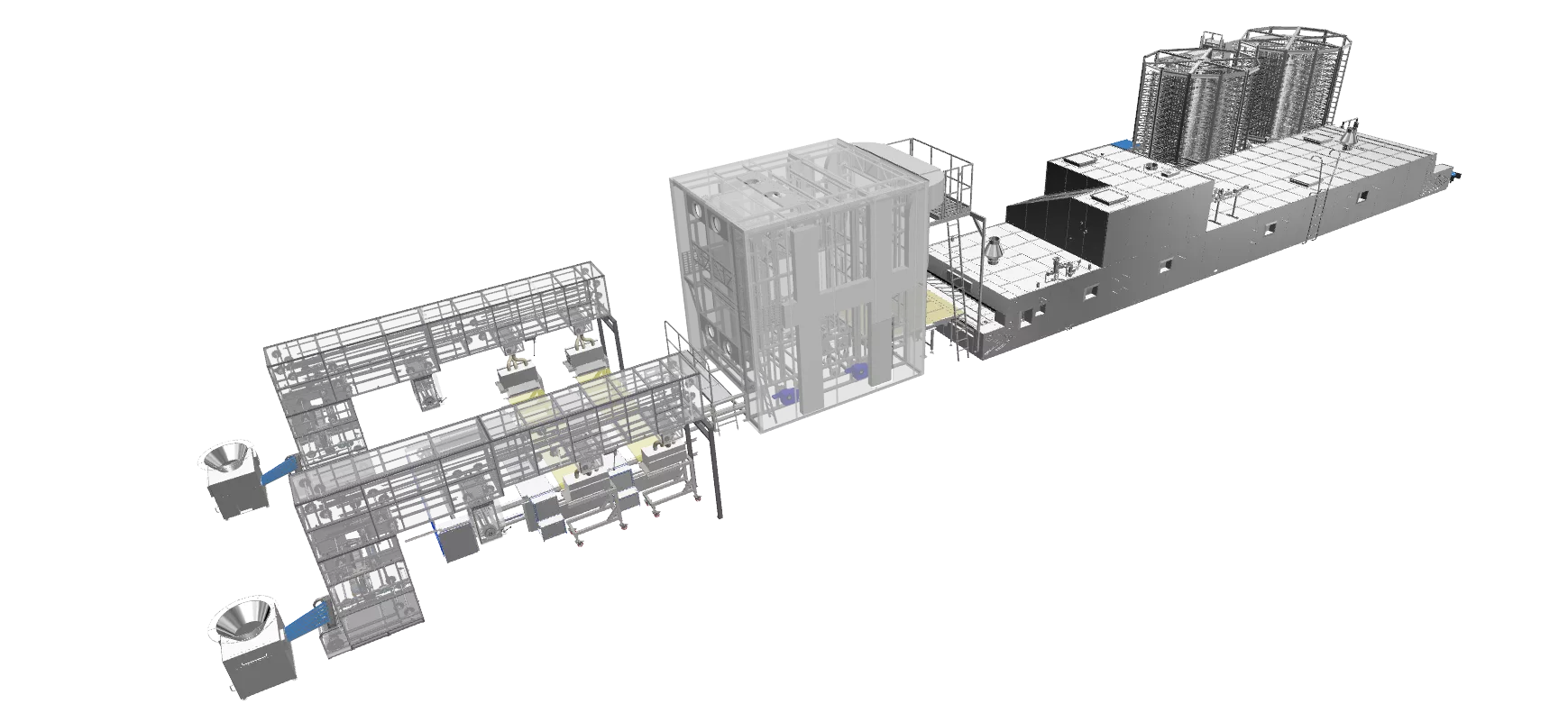

An intermediate tray proofer pre-proofs dough balls prior to their molding. It is an L-shaped unit, and is made up of horizontally-travelling trays. The intermediate proofer can be equipped with pre-molding for the production of oval stamped shapes, which may be installed at the entrance to, or inside the intermediate proofer.

Traditional Czech crescent-shaped roll production

Three rows of dough balls fall from separate openings into a three-row bread roll unit that produces white bread crescent rolls in the traditional, time-tested manner.

Three-row white bread crescent roll machines come in either (i) fabric or (ii) metal versions.

Production of stamped products

Pre-proofed dough balls are transferred smoothly via drum onto a transfer conveyor, from which they are placed into stamping trays. Using a drum mechanism ensures that all of the dough balls are positioned in straight rows prior to their entry into the molding machine. The conveyor beneath the stamping arm is comprised of polyamide trays that can be used for stamping round shapes on one side, and for oval shapes on the other. The stamping arm is situated on a rotating head, and is easily and quickly interchangeable.

In order to achieve a product with the required dimensions, shape, and appearance, it is important focus on choosing the proper type of continuous proofer. The most common type of proofer for the production of rolls and similar baked goods is the swing proofer, though sometimes peelboard proofers are suitable as well.

For more information, see Proofers.

The moistening and seeding units are situated on a separate conveyor with a roller conveyor. A height-adjustable brush moistens the product and removes flour from its surface. Our seeding units are compatible with various types of toppings (sesame seeds, poppy seed, pumpkin seeds and other types of toppings). A separate driving mechanism allows for the regulation of spacing between the products.

Once the products are proofed, they can be baked in cyclothermic, electric, or thermal oil tunnel ovens. We work with worldwide tunnel oven manufacturers, and together we have the ability to conceive the perfect solution for your bakery.

LS's manufacturing program also includes bread production lines using deck ovens. A wide-ranging product portfolio, insufficient space for a tunnel oven, or local customs are all possible reasons for choosing a deck oven over a tunnel oven. Today, the combination of an automated proofer and product positioning units suitable for deck oven use is a highly sought-after alternative to the traditional mode of production using tunnel ovens.

Our line allows for the products to be transferred between the proofer and the oven loading unit using LS's specialized transfer conveyor that sits upon a rail system that is fully synchronized with the entire line.

Spiral coolers involve either cooling in open air in situations where natural cooling is desired, or in an isolated chamber with a cooling unit if the final result of the cooling process necessitates a product of a specific temperature.

For more information, see Cooling Systems.